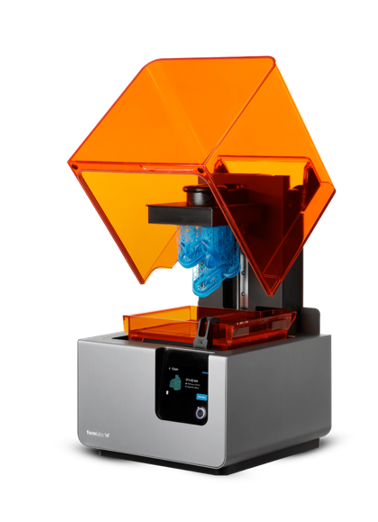

3D Printer – Form 2 [NI-SERV-2020-30]

Stereolithography (SLA) 3D Printing

SHORT DESCRIPTION

The Form 2 is a stereolithography (SLA) 3D printer that fabricates high-resolution parts by curing liquid photopolymer resin with a laser, layer by layer – a process known as photopolymerization. This technique is ideal for producing detailed prototypes, functional models, and complex geometries with smooth surface finishes. SLA printing is widely used across various fields, including engineering, product design, dentistry, jewelry, education, and research.

SPECIFICATIONS

- Technology: Stereolithography (SLA)

- Build Volume: 145 × 145 × 175 mm

- Layer Thickness (Z-resolution): 25 / 50 / 100 µm

- Laser Type: 405 nm violet laser, 250 mW (Class 1, EN 60825-1 certified)

- Laser Spot Size: 140 µm (FWHM)

- Operating Temperature: Self-heating resin tank, auto-heats to ~35 °C

- Dimensions: 35 × 33 × 52 cm

- Weight: 13 kg

- Power Supply: 100–240 V | 1.5 A | 50/60 Hz | 65 W

- Connectivity: Wi-Fi, Ethernet, USB

- Optical Path: Fully protected

- Supports: Auto-generated, easily removable

- File Formats: STL, OBJ

- Compatible Resins: Standard (Clear, Grey, White, Black), Engineering (Tough, Durable, Rigid, Flexible, High Temp), Specialty (Castable, Dental, Biocompatible, Ceramic)

- Software: PreForm

AVAILABILITY

Available for external users (upon payment);

Available for collaboration projects with industrial partners.

RESEARCH CENTRE

CENIMAT