Crystalsense – electronic nose using novel gas sensing materials

A new sensing solution for a bio-inspired electronic nose, able to “smell” mixtures of volatile organic compounds.

BACKGROUND

Gas sensors are used to measure the concentration of various gases in their surroundings. These devices are widely used across various end-use sectors, particularly in industries where various toxic and combustible gases need to be monitored and leaks prevented, such as industrial, petrochemical, and automotive industries. The overall gas sensors market expected to grow from USD 812,3 Million in 2016 to USD 1.297,6 Million by 2023, at a CAGR of 6,83% between 2017 and 2023. This growth is mainly attributed to the increase awareness on safety among end-users as well as stricter safety regulations imposed by government and regulatory bodies, particularly in North America and Europe. Gas sensors include fixed gas sensors as well as portable, non-invasive and wirelessly operated devices, which represent a fantastic window opportunity for growth.

TECHNOLOGY OVERVIEW

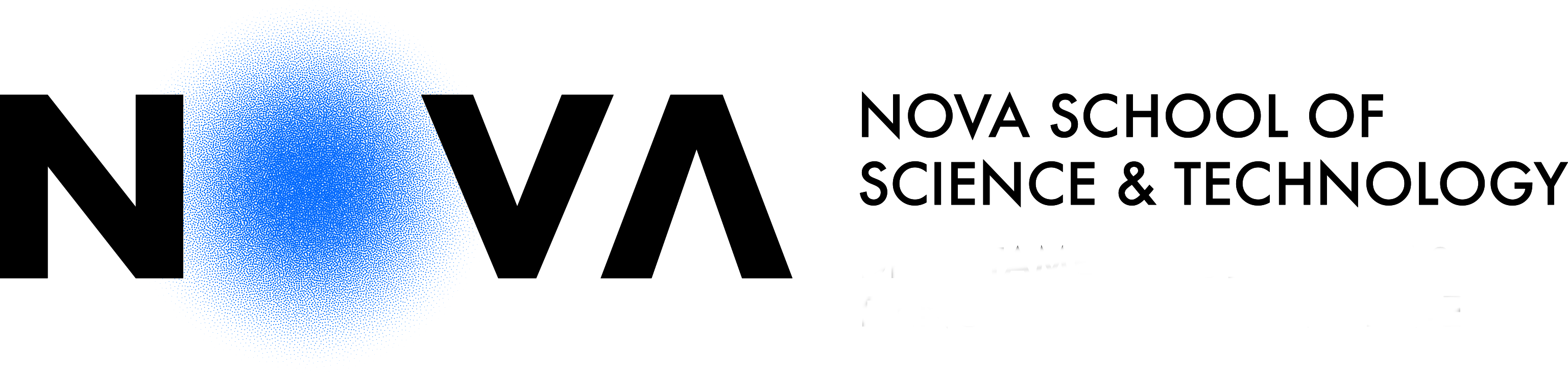

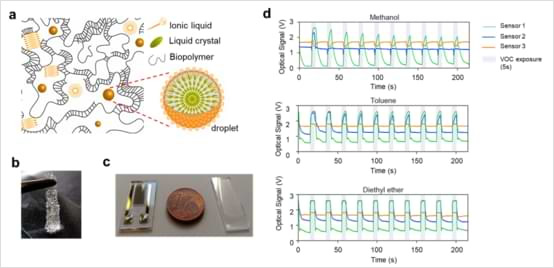

CrystalSense relates to gel-like materials that can sense gases, yielding optical and/or electrical signals in the presence of volatile organic compounds (VOCs) and also to a method to employ the gel-like materials as gas sensors in electronic noses (e-noses), including the in-house design and fabrication of optical and/or electrical signal acquisition devices, the development of dedicated signal processing and machine-learning algorithms. CrystalSense enables customizable solutions for different applications. It is possible to formulate libraries of gels with distinct chemical properties and rationally design gels with optimized chemical affinity towards target VOCs and the combination of signals generated from gels with distinct formulations forms patterns that can work as a fingerprint for distinct odours.

FURTHER DETAILS

- Esteves C, Santos GMC, Alves C, Palma SICJ, Porteira AR, Filho J, Costa HMA, Alves VD, Faustino BMM, Ferreira I, Gamboa H, Roque ACA 2019. Effect of film thickness in gelatin hybrid gels for artificial olfaction. Materials Today Bio. 1. (OPEN ACCESS)

- Hussain, A, Semeano ATS, Palma SICJ, Pina AS, Almeida J, Medrado BF, Pádua AC, Carvalho AL, Dionísio M, Li RWC, Gamboa H, Ulijn RV, Gruber J, Roque ACA. 2017. Tunable Gas Sensing Gels by Cooperative Assembly. Advanced Functional Materials. 1700803:1–9.(OPEN ACCESS)

- Santos GMC, Alves C, Pádua AC, Palma SICJ, Gamboa H, Roque ACA. 2019. An optimized E-nose for Efficient Volatile Sensing and Discrimination. Proceedings of the 12th International Joint Conference on Biomedical Engineering Systems and Technologies- Volume 1: BIODEVICES: 36-46 (OPEN ACCESS)

- Pádua, AC, Palma SICJ, Gruber J, Gamboa H, Roque ACA. 2018. Design and Evolution of an Opto-electronic Device for VOCs Detection. Proceedings of the 11th International Joint Conference on Biomedical Engineering Systems and Technologies:48-55. (OPEN ACCESS)

- Pádua, AC, Osório D, Rodrigues J, Santos G, Porteira AR, Palma SICJ, Roque ACA, Gamboa H. 2018. Scalable and Easy-to-use System Architecture for Electronic Noses. In Proceedings of the 11th International Joint Conference on Biomedical Engineering Systems and Technologies. 179-186. (OPEN ACCESS)

- Semeano, ATS, Maffei DF, Palma SICJ, Li RWC, Franco BDGM, Roque ACA, Gruber J. 2018. Tilapia fish microbial spoilage monitored by a single optical gas sensor. Food Control. 89:72-76. (OPEN ACCESS)

STAGE OF DEVELOPMENT

TRL: 4/5 – Proof-of-concept.

BENEFITS

- Sensing Material – low cost and environmentally-friendly composition and production;

- E-nose Technology – identification of fingerprints from simple or complex gas mixtures;

- Customisible – tuneable selectivity and sensitivity for each application;

- Real time – fast optical and electrical responses to VOCs;

- Platform technology – custom-built for desired applications.

APPLICATIONS

This technology is useful for situations where information on the species present in a sample is required, particularly for samples in the vapor or gas phases. Examples include (but are not limited to):

- Manufacturing Industry (mainly in quality control, detection of hazardous agents), food processing, chemicals, refineries and petrochemical plants, pharmaceutical and biopharmaceutical industry, biotech companies and the wood industry, among others. The typical gas sensors for industrial applications include carbon dioxide gas sensors, oxygen gas sensors, hydrogen gas sensors and others;

- Security – entry ports (such as airports); military and national security;

- Environment – Risks and detection of pollutants, control of waste facilities and reservoirs of water treatment as well as in rivers and lakes;

- Non-invasive medical diagnostic and therapeutic devices for use in clinical settings and home care;

- Scientific research – Sensors in R&D useful for distinction of materials, botanical and ecological studies, as well as analytical methods in (bio)processing;

- Automotive – gas sensors used in automotives. The common gas sensors used in automotives include oxygen sensors and methane sensors;

- Building automation – gas sensors used in residential and commercial building automation applications;

- Food quality – assessment and sensorial assessment;

- Textiles – smart textiles;

- Well-being – monitoring human body smells (pleasant/unpleasant);

- Product control – pharmaceutical industry;

OPPORTUNITY

- Seeking co-development partners;

- Available for exclusive and non-exclusive licensing.

INTELLECTUAL PROPERTY

NOVA Inventors

Ana Cecília Roque

Abid Hussain