New eddy currents probe for tubular geometries

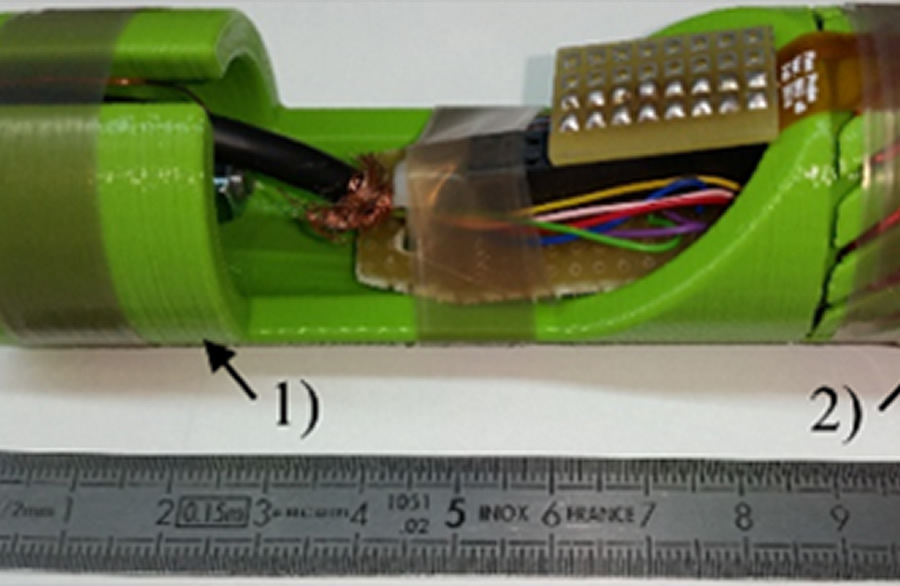

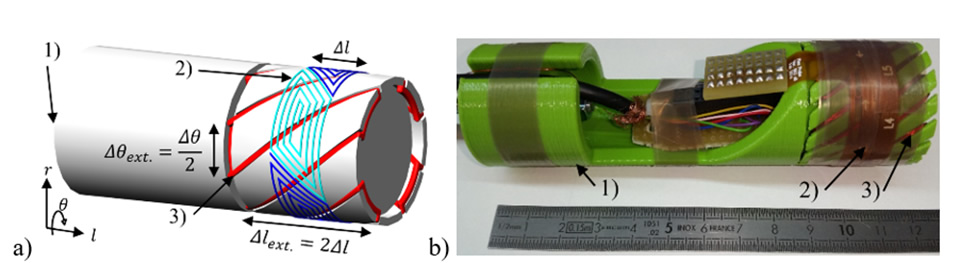

The invention consists of a new eddy currents probe for non-destructive testing of components with circular geometry. The probe is composed by 2 main features, the sensitive coil and the excitation winding which disposition allows a greater sensibility in the components testing.

Technology Overview

The probe is composed by 2 main features, the sensitive coil and the excitation winding.

The sensitive coil consists of an array of planar trapezoidal spiral coils on a flexible substrate around a cylindrical chassis.

The excitation coil consists of a winding twisted by an angle β = [40º – 70º]. The inclined excitation coil generates eddy currents in its direction, which are disturbed by axial and tangential defects. The excitation angle must be such that, a defect passing through the sensitive coil crosses the excitation coil at least once. This allows to make sure that there are currents flowing through the defect at some point, while under the sensitive coil.

The chassis can be produced in Polylactic Acid (PLA) by additive manufacturing, using 3D printing by Fused Deposition Modelling (FDM) which allow a greater complexity of the chassis.

This solution allows the detection of micro defects that were not being detected with existing solution.

This probe also allows the detection of defects with any orientation and provides information on both axial and tangential position.

The probe is also easily customizable, economic and cost effective.

Operates on materials with very low magnetic permeability, similar to air (μr ≈ 1), and low electric conductivity.

Stage of Development:

TRL6 – Prototype developed and tested under several conditions with different age groups of users. Some improvements to the graphical interface of the software must be performed.

Intellectual Property

Patent granted in Portugal (PT109373).

NOVA Inventors

Ewa Bogel-Lukasik